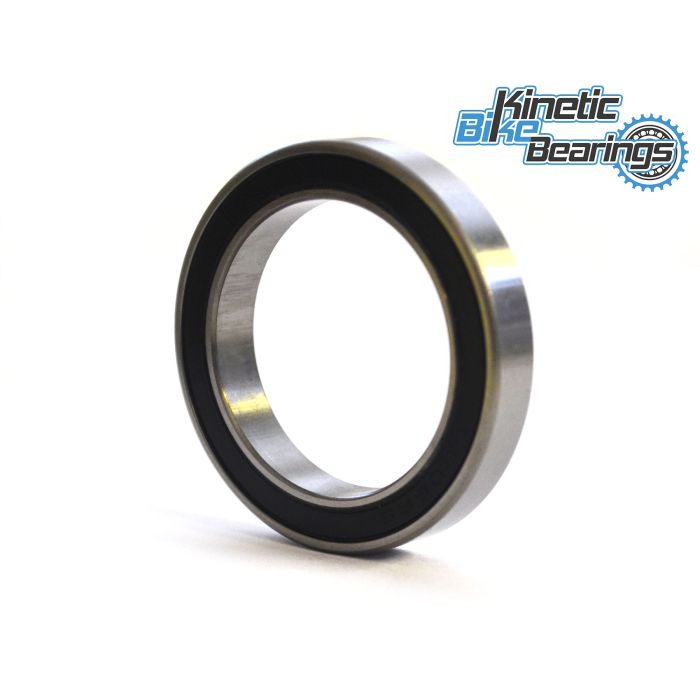

7806 2RS | Bottom Bracket Bearing | Angular Contact 6806

7806 2RS | Bottom Bracket Bearing | Angular Contact 6806

ANGULAR CONTACT VERSION OF 6806/BB30

Also known as 71806

Note: This is an internally angular contact version of 6806 - will take vertical and horizontal loads - an answer to get longer life from a BB30 bottom bracket. This bearing can only be inserted one way - observing the inner race, there is a different thickness on either side. The side with the thicker inner race should be on the outside facing you when installing (due to internal chamfer angle).

In long description, scroll to bottom of page to see direct fit alternatives.

Inner x Outer x Depth (mm): 30x 42 x 7mm

Used on: Bottom Brackets

- Inner Diameter x Outer Diameter x Depth: 30x 42 x 7mm

- Used on: Bottom Brackets

- Note: This is an internally angular contact version of 6806 - will take vertical and horizontal loads - an answer to get longer life from a BB30 bottom bracket

- Precision Tolerance: ABEC3

- Ball Roundness : Grade 10

- Seals: 2RS

- Grease: Low friction, temperature stable grease

- Material: 52100 High Carbon Chromium Alloy Races

- Note, This listing is for single bearings, and not pairs.

What is ABEC?

The ABEC grade of bearings is a set of standards for the manufacturing tolerances of bearings. There are five classes from largest to smallest tolerances: 1, 3, 5, 7, and 9. The higher ABEC classes provide better precision, efficiency and greater speed capabilities, but do not necessarily make the components spin faster. All quality manufacturers around the world manufacture to at least ABEC 1 standard. Enduro’s Minimum Standard is ABEC 3.

What is the meaning of Ball Grade?

Bearing balls are manufactured to a specific grade, which defines its geometric tolerances (or roundness). The smaller the number the higher the precision. A grade 20 ball for instance is 20/1,000,000" out of round. Enduro use Grade 10 for ABEC 3.

Seals

2RS: Literally means the bearing has Two Rubber Seals. There are many types of seals.

Bearing Installation and Removal

Bearings should never be installed by pressing on the inner race. Always press on the outer race with a pilot bushing or similar tool, which will only make contact with the metal side of the outer race. A bearing press or similar should be used to exert the force needed to press the bearing into the housing. Ensure that the seating surface is clean and free from rough edges so that they fit true and square. Quite often bearings can feel fine before fitting, but then feel "notchy" or "rough" after fitting. This is almost always due to the bearings not sitting square and true. Care needs to be taken that the bearing is started straight and not at an angle to the housing.

Bearing Care

To prolong the life of your bearings, do not direct a high jet of water near areas of your bike where there bearings are located - an ingress of water can lead to premature bearing failure.

| size | 1 |

|---|